Our Mission

GenSensor was founded with a vision to become a game changer in the field of genomic based in-line bioproduction monitoring.

Our company combines the development of a robotic device with an advanced analytics software to monitor, characterize, optimize your bioproduction of ATMP and vaccines.

Gensensor is a mission-driven company with the following objective:

To promote access to innovative biologic medicines by optimizing bioproduction for the benefit of patients.

Our Team

Powered by our people

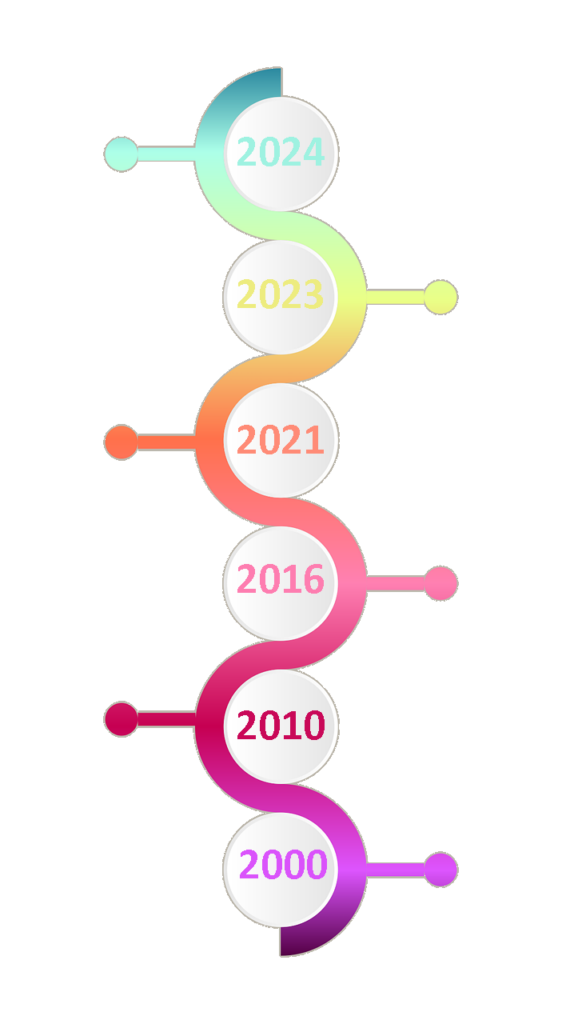

History

1st sequencing made

by Charles & Jean-Marie

Switch to NGS

(Next Generation Sequencing)

Application of NGS

to control drug quality

GenSensor creation

in St Herblain

Fundraising

Move to a new facilities in Nantes +

growth of the team (15 employees) +

launch of GenSampler

Time flies!

Combining our backgrounds and experiences, we founded GenSensor in 2021 aiming to improve access to ATMP (Advanced Therapy Medicinal Products).

A throwback to the last 3 years reveals perseverance, hard work and need to offer a reliable service to our clients.

Today, we count 15 employees coming from different backgrounds and sharing same values.

Adding to this, we’re equipped with all the resources that allow us to move forward effectively and rapidly in order to meet your needs.

Why Gensensor?

Our mutual experience in biotech industry has forced us to develop a new technology like no other. It is based on the use of cells, the biopharmaceutical production unit.

Today, many technologies are available to control either the physicochemical conditions of cell culture or cell phenotype. However, do these techniques really provide enough information to control and master the bioproduction?

That’s why GenSensor was created. By monitoring in real-time the expression level of specific genes, drug production will be controlled at its best.

We are here to help you mastering your bioproduction

Facilities

Located in Nantes-France, our facility is well equipped with all the resources and the team considered all aspects of mechatronics, microfluidics, cellular & molecular biology and informatics, in compliance with pharmaceutical industries standards.

Quality

Our robust Quality Management System (QMS) governs all the development areas at GenSensor:

Provide our clients / users reliable and innovative services responding to the quality standards of our company

Ensure the compliance of the regulatory and legal requirements while guaranteeing the transparency in our actions

Listen to customers and respond continuously to their needs and desires by integrating them into each step of GenSensor life cycle

Do evolve our human resources by developing the skills and expertise of our employees

Maintain out facility, equipment and processes at the standards of our company by ensuring the traceability of the processes and products